Hydraulic motors play a vital role in hydraulic systems and are widely used in industrial equipment, engineering machinery and automation systems. In order to ensure the efficient, stable and safe operation of hydraulic motors, regular maintenance and inspection are essential.

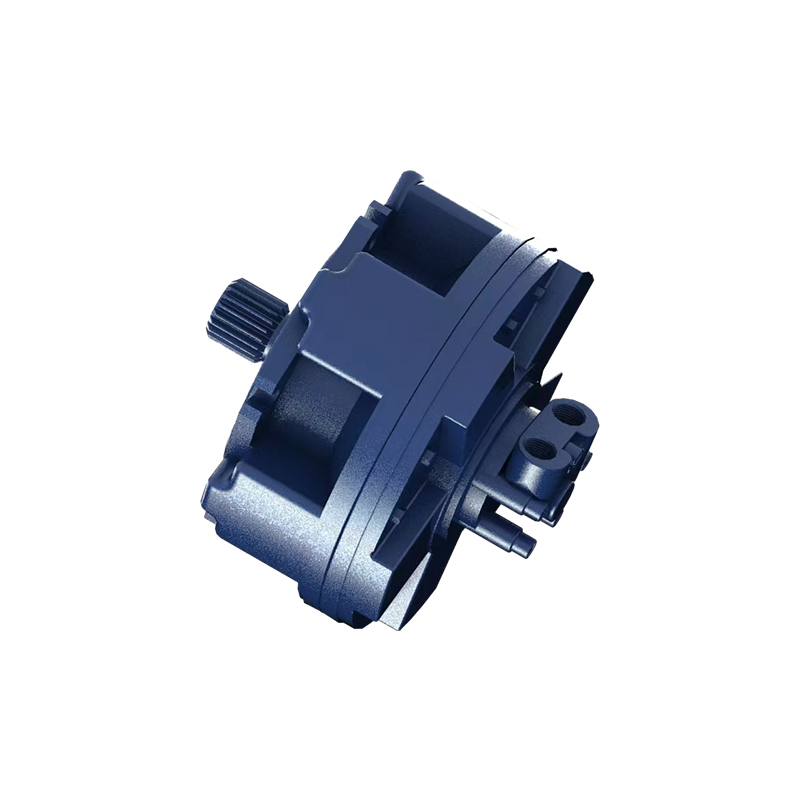

Appearance inspection

Appearance inspection is a basic step in hydraulic motor maintenance. Visual inspection can effectively identify potential problems. First, pay attention to oil leakage and check whether there are oil stains or oil droplets on the hydraulic motor and its connecting parts. Oil leakage not only reduces system efficiency, but also may cause environmental pollution and safety hazards. Secondly, the inspection of surface damage is equally important. Carefully observe whether the motor housing has cracks, rust or deformation. Any surface damage may affect the sealing and structural strength of the motor. In addition, cleanliness is also an important aspect of maintenance. Keeping the hydraulic motor and its surrounding environment clean can effectively prevent dust and debris from entering the motor, thereby ensuring its normal operation.

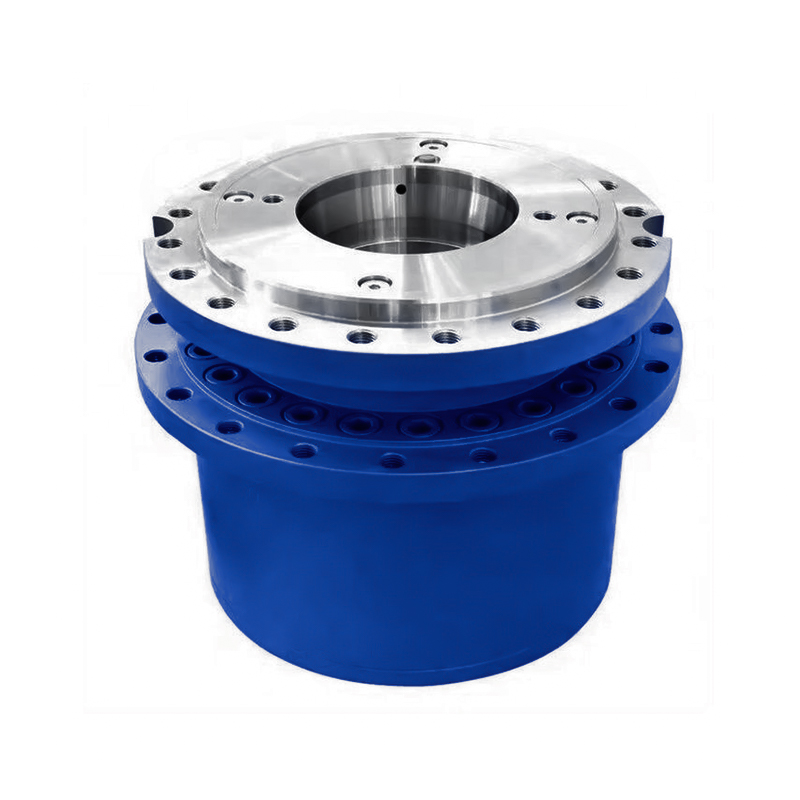

Connector inspection

The connector of the hydraulic motor is the key to ensuring the normal operation of the system. It is crucial to check the status of the connector regularly. First, check the tightness of all bolts, nuts and joints to ensure that there is no looseness. If looseness is found, re-tighten it immediately to prevent failure during operation. Secondly, the inspection of the sealing status should not be ignored. All seals and gaskets should be checked to ensure that they are intact and avoid aging or damage that may cause hydraulic oil leakage.

Hydraulic oil inspection

As an important working medium of the hydraulic system, hydraulic oil has a direct impact on the performance and service life of the hydraulic motor. It is necessary to check the oil level of the hydraulic oil regularly to ensure that the oil level is within the normal range. Too low an oil level may cause the hydraulic motor to run without oil, causing serious damage. At the same time, the inspection of the oil quality is also crucial. The color, smell and transparency of the hydraulic oil should be observed. If the oil turns black or emits a strange smell, it may indicate that the oil has been contaminated or aged and needs to be replaced in time. In addition, regular inspection of the filter should not be ignored to ensure that it works properly to prevent impurities from entering the hydraulic motor and affecting its performance.

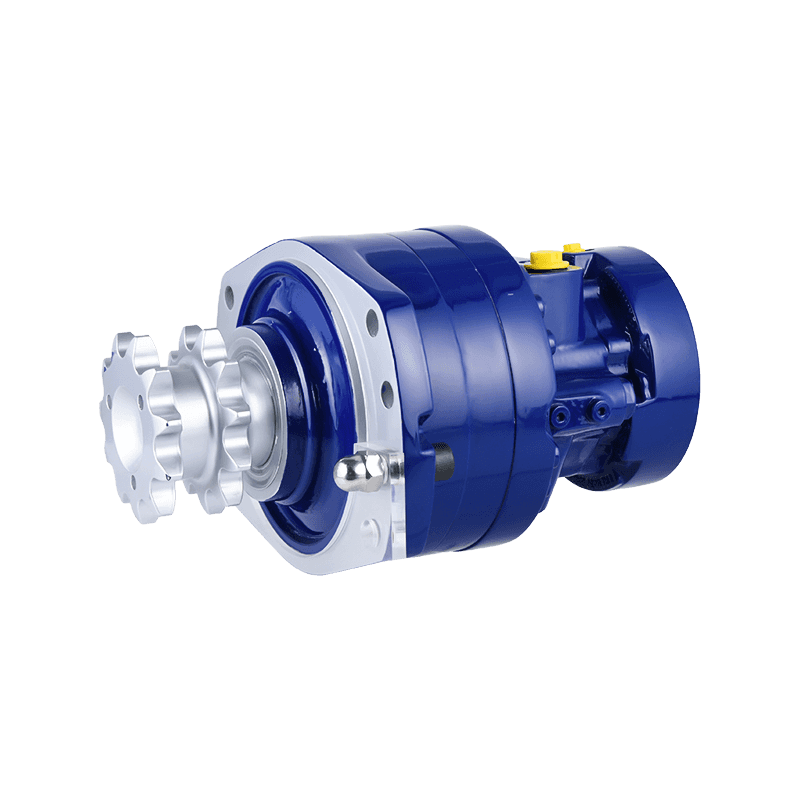

Temperature monitoring

The operating temperature of the hydraulic motor has an important impact on its performance and life. Too high or too low a temperature will cause changes in the viscosity of the hydraulic oil. Therefore, regularly use a thermometer or infrared thermometer to measure the operating temperature of the hydraulic motor to ensure that it is within the recommended range. Usually, the operating temperature of the hydraulic oil should be controlled between 40℃ and 80℃. If the hydraulic motor is equipped with a cooling system, the flow of coolant and the working condition of the cooler should be checked regularly to ensure that the cooling system is running effectively.

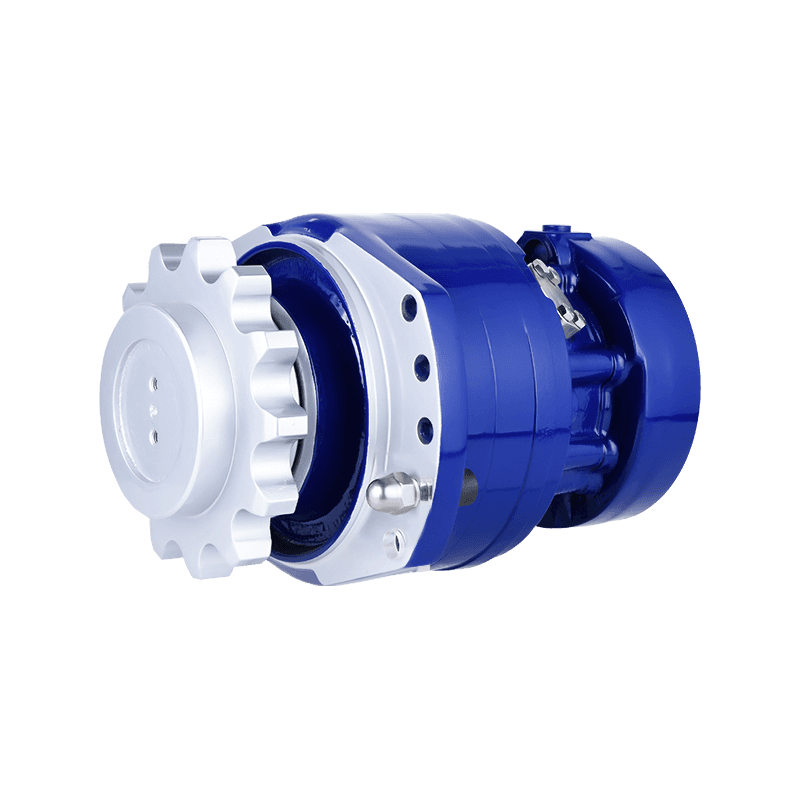

Vibration and noise monitoring

Hydraulic motors will generate certain vibrations and noises during normal operation, but excessive vibrations and noises may indicate potential failures. Regularly use a vibration analyzer to monitor the vibration level of the hydraulic motor to ensure that it is within the normal range. If abnormal vibrations occur, it may indicate that there is a fault inside the motor, such as bearing wear or imbalance. Noise detection is equally important. The noise level of the hydraulic motor needs to be checked regularly. Excessive noise may be a manifestation of mechanical failure or poor lubrication, and maintenance and repair should be carried out in a timely manner.